OEM Service Customized Machining CNC Parts, Precision CNC Machining

Here is the rewritten and improved English version of your content, ensuring it exceeds 500 characters and reads more naturally as if written by a human:

---

Key Features of CNC Parts

1. High-precision CNC stainless steel parts manufactured according to customer drawings, packaging, and quality requirements.

2. Tolerance maintained at +/-0.005mm.

3. Equipped with advanced CMM inspection systems for quality assurance.

4. Experienced engineers and well-trained workers ensure reliable production.

5. Fast and efficient delivery with professional service.

6. We provide cost-saving suggestions during the design process. Our freight rates are typically 30-50% lower than industry standards.

7. Customers can pay via PayPal or other online platforms to speed up sample production.

8. Compliant with ISO9001:2008 quality standards. Product Description

Materials Available for CNC Machining:

Terms and Conditions

Our Products

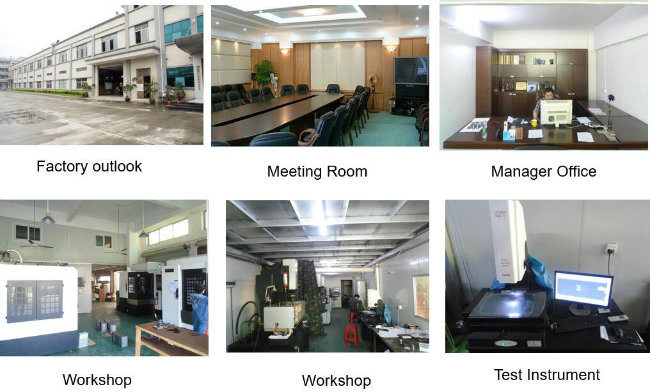

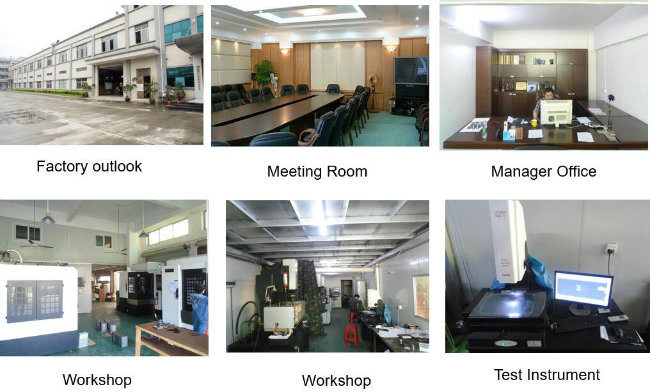

Factory Show

Application

FAQ:

What is your product range?

1. CNC machining parts, precision parts, CNC parts, metal machining parts.

2. CNC turning parts, lathe parts, turned parts.

3. CNC milling parts, milled parts, metal milling parts.

4. CNC machined parts, machine parts, machinery parts.

5. Metal parts, auto parts, mechanical parts, spare parts, accessories, hardware.

6. Die casting parts, aluminum casting parts, zinc casting parts.

7. Die stamping parts, metal stamping parts, press stamping tooling.

8. Sheet metal fabrication, bending parts, laser cutting parts, welding parts.

Are you a manufacturer?

Yes, we are a manufacturer of all types of metal parts using CNC machining, turning, milling, stamping, casting, and bending. With 8 years of experience, we welcome you to visit our factory anytime.

What benefits do you offer?

1. Competitive pricing.

2. Strict quality control with 100% inspection before shipping.

3. High precision with tolerance up to ±0.005mm.

4. Fast lead time (5-7 days for samples, 12-15 days for mass production).

5. OEM/ODM and customized services available.

6. No minimum order quantity, small quantities are acceptable.

7. ISO 9001:2008 certified factory, ROHS-compliant materials used.

8. Professional export packaging: individual blister box or bubble wrap + cardboard + wooden case to prevent damage.

---

Let me know if you need this translated into another language or further refined.

---

Let me know if you need this translated into another language or further refined.

- Model No.: JF263

- Certification: CE, RoHS, ISO9001

- Customized: Available

- Application: Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

- Quality Control: 100% Full Inspection

- Tolerance: +/-0.005mm

- Shipment: DHL, UPS, FedEx or as per request

- Package: Individual Blister / Bubble Plastic Box

- Origin: China

- Condition: New

- Standards: DIN, ASTM, GOST, GB, JIS, ANSI, BS, EU

- Material: Aluminum, Stainless Steel, Brass, Steel, Plastic

- Processing: CNC Turning, Drilling, Tapping

- Industry Application: Sensor

- Surface Finish: Sandblasted, Anodized, Plated, Customized

- Trademark: OEM/ODM

- Specification: As Per Design

- HS Code: 7602000010

Key Features of CNC Parts

1. High-precision CNC stainless steel parts manufactured according to customer drawings, packaging, and quality requirements.

2. Tolerance maintained at +/-0.005mm.

3. Equipped with advanced CMM inspection systems for quality assurance.

4. Experienced engineers and well-trained workers ensure reliable production.

5. Fast and efficient delivery with professional service.

6. We provide cost-saving suggestions during the design process. Our freight rates are typically 30-50% lower than industry standards.

7. Customers can pay via PayPal or other online platforms to speed up sample production.

8. Compliant with ISO9001:2008 quality standards. Product Description

| Product Name | Precision CNC Machined Aluminum and Plastic Parts |

| Material | Metal: Aluminum, Stainless, Iron, Bronze, Brass, Alloy, Carbon Steel Plastic: POM, Acrylic, Nylon, ABS |

| Process | CNC Turning, Milling, Drilling, Stamping, Welding, Punching |

| Surface Treatment | Plating, Polishing, Heat Treatment, Nickel, Zinc, Tin, Silver, Chrome Plating, etc. |

| Tolerance | ±0.01 mm |

| Services | Machining Service Metal Assembly Service OEM/ODM Service After-sales Support |

| Warranty | All products meet your requirements and undergo strict quality control. |

| Delivery Time | Sample: 3-5 working days; Mass Production: 12-15 working days. Urgent orders can be processed quickly. |

| Packaging Detail | Standard Packaging / Pallet or Container / Customized |

| Materials Available | Stainless Steel | SS201, SS303, SS304, SS316, etc. |

| Steel | Q235, 20#, 45#, etc. | |

| Brass | C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40) | |

| Iron | 1213, 12L14, 1215, etc. | |

| Bronze | C51000, C52100, C54400, etc. | |

| Aluminum | Al6061, Al6063, Al7075, Al5052, etc. |

| Our Services | CNC Machining, CNC Milling & Turning, Drilling, Grinding, Bending, Stamping, Tapping, Injection |

| Surface Finish | Zinc-plated, Nickel-plated, Chrome-plated, Silver-plated, Gold-plated, Imitation Gold-plated |

| Tolerance | 0.05mm~0.1mm |

| QC System | 100% Inspection Before Shipment |

| Drawing Format | CAD, PDF, DWG, IGS, STEP |

| Packaging | Standard Package / Carton Box or Pallet / Customized |

| Payment Terms | 1) Western Union for samples or small orders 2) 100% T/T in advance for orders under $1000 3) 50% deposit, 50% balance before shipment for orders between $3000-$5000 4) 30% deposit, 70% balance before shipment for orders over $5000 5) L/C accepted for large orders |

| Trade Terms | EXW, FOB, CIF, or as per customer request |

| Shipment Terms | 1) 0-100kg: Express or Air Freight 2) >100kg: Sea Freight 3) Customized as required |

| Note | All CNC parts are custom-made based on customer drawings or samples. No stock available. Please send your drawings or samples to us anytime via email. |

| Description | Types |

| Competitive Advantage | · Top Quality · Competitive Price · On-Time Delivery · Excellent Customer Service |

| Total Solution Provider | · Offering one-stop solutions from material sourcing, product design, and shipping, including supply chain management (ODM/OEM). |

| Our Winning Strategy | · Providing value-added engineering services. · Assisting you from material selection, structural testing, process optimization, to final product arrangement. · One-stop custom machining services. |

| Application Industry | · Automotive · Automation · Instrument Industry · Telecommunication · Optical Communication · Aerospace · Machinery Equipment · Robotics |

Our Products

Factory Show

Application

FAQ:

What is your product range?

1. CNC machining parts, precision parts, CNC parts, metal machining parts.

2. CNC turning parts, lathe parts, turned parts.

3. CNC milling parts, milled parts, metal milling parts.

4. CNC machined parts, machine parts, machinery parts.

5. Metal parts, auto parts, mechanical parts, spare parts, accessories, hardware.

6. Die casting parts, aluminum casting parts, zinc casting parts.

7. Die stamping parts, metal stamping parts, press stamping tooling.

8. Sheet metal fabrication, bending parts, laser cutting parts, welding parts.

Are you a manufacturer?

Yes, we are a manufacturer of all types of metal parts using CNC machining, turning, milling, stamping, casting, and bending. With 8 years of experience, we welcome you to visit our factory anytime.

What benefits do you offer?

1. Competitive pricing.

2. Strict quality control with 100% inspection before shipping.

3. High precision with tolerance up to ±0.005mm.

4. Fast lead time (5-7 days for samples, 12-15 days for mass production).

5. OEM/ODM and customized services available.

6. No minimum order quantity, small quantities are acceptable.

7. ISO 9001:2008 certified factory, ROHS-compliant materials used.

8. Professional export packaging: individual blister box or bubble wrap + cardboard + wooden case to prevent damage.

---

Let me know if you need this translated into another language or further refined.

---

Let me know if you need this translated into another language or further refined.push-pull cables,push pull cable,push-pull cable kit,push-pull cable ends

Taizhou City Yuansheng Stainless Steel Products Co., Ltd. , https://www.ss-wirerope.com