Flyability's Elios 2 Cuts Downtime by 80% in Drilling Rig Ballast Tank Inspections

DR1 Group significantly reduced downtime for a ballast tank inspection on a drilling rig by 80% using the Elios 2—read the full case study to discover how this innovative solution transformed their process.

Key Benefits at a Glance

|

Savings 60% cost reduction in ballast tank inspections thanks to the use of the Elios 2. |

Reduced Downtime 80% decrease in downtime, reducing the inspection time from five days to just one day. |

Safety No need for confined space entry or rope access—enhancing safety for workers. |

Introduction

In the oil and gas industry, offshore drilling rigs are essential for extracting resources from the seabed. These massive structures operate in both shallow and deep waters, with different designs depending on their environment.

In shallow water, drilling rigs are typically supported by columns that extend down to the ocean floor. However, in deeper waters, they float, relying on stability systems such as ballast tanks to maintain balance and buoyancy.

These ballast tanks, located in the columns and pontoons, play a critical role in keeping the rig stable. Regular inspections are necessary to ensure their structural integrity and operational safety.

The drilling rig DR1 Group inspected

Given the complexity and risks involved in inspecting these internal spaces, traditional methods like rope access were not only time-consuming but also dangerous for workers.

Customer Needs

In Brazil, a shipyard in Angra dos Reis was seeking a safer and more efficient way to inspect its drilling rigs. Previously, inspectors would descend into the ballast tanks using ropes—a method that posed significant safety risks and extended downtime.

To address these challenges, the shipyard reached out to DR1 Group, asking them to conduct a test inspection using drones. Their goal was to evaluate whether drone technology could offer a better alternative for future inspections.

Solution

After an initial planning meeting, DR1 Group collaborated closely with the shipyard to plan two test missions: one for external inspections of the rig’s towers and other exposed areas, and another for internal inspections of the columns and ballast tanks.

The team worked for two months to ensure all legal requirements and safety standards were met, preparing for safe and compliant drone operations.

During the tests, the goal was to collect enough visual data to prove that drones could effectively replace traditional methods, providing clear and accurate insights without putting workers at risk.

Results

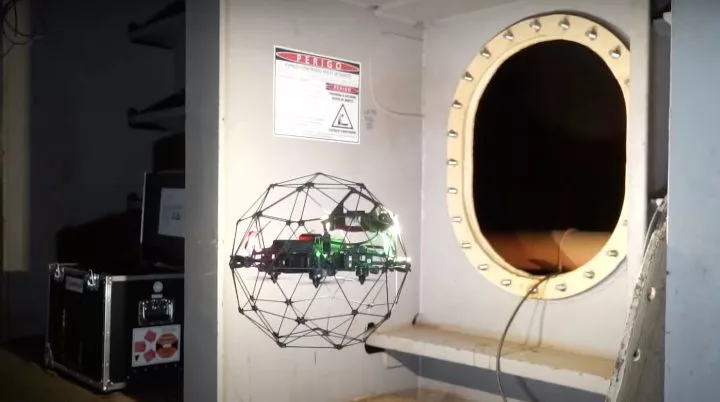

While the external inspection was conducted using a DJI Matrice 210, the internal inspection was carried out using Flyability’s Elios 2. The results were impressive.

Within 30 minutes of flight time, the DR1 team successfully inspected 40% of a ballast tank. The entire mission took about two hours, including battery swaps and footage reviews to ensure full coverage.

Based on these results, the shipyard estimated that using the Elios 2 could reduce the total inspection time from 60 days to just 20 days. This represents a major improvement in efficiency and cost-effectiveness.

Here is a video showcasing the ballast tank inspection:

Following the test, DR1 presented the collected visual data to the shipyard administrators, who were very satisfied with the improved safety, efficiency, and cost savings achieved through the use of the Elios 2.

Some of the high-quality images captured during the inspection include:

Conclusion

The test missions took place in early 2020, but due to the impact of the COVID-19 pandemic, work was temporarily halted. However, the shipyard has since resumed operations and plans to bring DR1 Group back for future inspections.

With several other rigs in their fleet, the shipyard is considering hiring DR1 Group to perform similar inspections using the Elios 2 across all their vessels. Additionally, DR1 Group continues to use the Elios 2 for confined space inspections in various oil and gas applications, proving its versatility and effectiveness in challenging environments.

Warp Knitting Machine Application

Warp knitting machines are widely used in the textile industry for producing fabrics with different types of yarns. These machines are used for creating a variety of fabrics that are used in various applications such as clothing, home textiles, technical textiles, and industrial textiles. Some of the common applications of warp knitting machines are:

1. Clothing: Warp knitting machines are used for producing a wide range of clothing fabrics such as dresses, skirts, blouses, and sweaters. These machines can produce fabrics with different patterns, textures, and colors, which are used in fashion apparel.

2. Home textiles: Warp knitting machines are used for producing fabrics that are used in home textiles such as curtains, bed sheets, tablecloths, and upholstery. These fabrics are known for their durability, softness, and comfort.

3. Technical textiles: Warp knitting machines are used for producing technical textiles such as geotextiles, medical textiles, and protective textiles. These fabrics are designed to have specific properties such as strength, durability, and resistance to chemicals and heat.

4. Industrial textiles: Warp knitting machines are used for producing fabrics that are used in industrial applications such as filtration, insulation, and reinforcement. These fabrics are designed to have specific properties such as high strength, heat resistance, and chemical resistance.

Overall, warp knitting machines are versatile machines that are used in various applications in the textile industry. They are known for their high productivity, flexibility, and ability to produce fabrics with different properties.

Warp Knitting Machine Application,Application Of Warp Knitting Machine,Raschel Curtain Machine,Textronic Curtain Machine

suzhou cotex international Co.,Ltd , https://www.cotexmill.com